Silicone for Concrete & Stone Molding

Tin cured RTV-2 silicone for making concrete, artificial stone moulds

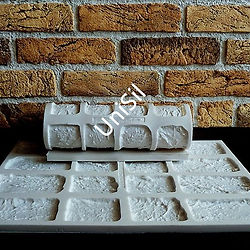

Product Preview

UniSil T-M Series Tin-Cured Silicone Molds: Durable, Cost-Effective Solutions for Precision Mold Making Product Overview: UniSil T-M Series (T-M25, T-M30, T-M35) are premium tin-cured silicone rubbers engineered for high-performance mold creation in demanding applications like concrete panels, artificial stone, and plaster casting. With superior fluidity, rapid bubble release, and exceptional durability, these silicones are ideal for industrial manufacturers and craft artisans seeking long-lasting, economical molds. Key Features: ✅ Low-Viscosity Formula Perfect for casting intricate molds with fine textures (e.g., sculpture details, GRC patterns). Self-leveling consistency ensures seamless pours without manual spreading. ✅ Superior Bubble Release Technology Minimizes air entrapment for flawless concrete, gypsum, and fiberglass surfaces. ✅ Industry-Leading Tear & Tensile Strength Ideal for high-volume production of GRC facades or cement tiles. ✅ Budget-Friendly Performance 30% longer lifespan than standard silicones, reducing long-term costs for construction and prototyping projects. Applications: Construction & Architecture: Concrete decoration, GRC/GRG panels, artificial stone countertops. Art & Crafting: Detailed sculpture molds, candle/soap casting, plaster art reproductions. Industrial Prototyping: Furniture design, fiberglass components, wax models for metal casting. Technical Highlights: Certifications: RoHS-compliant (non-food-grade; not recommended for baking or high-temperature uses). Viscosity: 16,000-23,000 mPa·s (adjustable by model). Cure Time: 6-8 hours at room temperature. Why Choose UniSil T-M Series? "We replaced our old silicone with T-M35 for GRC facade production. Even after 500+ cycles, the molds retained sharp details and zero tears!" — Lopez Constructors, Spain